- Media Coverage

- Telemetry is driving better business outcomes As featured in Gasworld: April 2023

Telemetry is driving better business outcomes

As featured in Gasworld: April 2023

Challenges in the packaged gas supply chain are well known to distributors of all sizes. For most companies, two issues are always top of mind: the cost of deliveries and always tight margins. While these problems are nothing new, the use of sophisticated yet accessible technologies to help solve them is creating an important new mindset throughout the sector. Efficiency is the new watchword – and it’s carving the surest path to increased profits. Some of the most efficient gas distributors in the market are using Pulsa’s high frequency telemetry to enable important new efficiencies and, through them, are enjoying better business outcomes.

Creating addition through subtraction

Precision inventory monitoring and all its benefits – including trend tracking, proactive alerts and illuminating usage data – is resulting in increased profits for some distributors. This is being achieved through reductions in inefficiencies and costs while, at the same time, providing better service to their customers. In fact, enhanced customer service can rightfully be the prime draw of telemetry-driven gas delivery. When a distributor can provide always-optimized inventory while minimizing unnecessary refill sessions and reducing paperwork, customer satisfaction rises accordingly. For the distributor, these efficiencies – reduced number of deliveries, optimized routes and reduced mileage per truck roll – essentially reveal a profit center that was previously hidden. This “addition by subtraction” is not just a boon to today’s

“its benefits include trend tracking, proactive alerts and illuminating usage data”

bottom line. Over time, it becomes an ongoing savings generator that can self-fund further digital transformation throughout the gas distributor’s enterprise. One distributor that has integrated telemetry solutions into its business is MacCarb. Based in Illinois, MacCarb is active in several markets and prides itself on “keeping the fizz in your bizz”. In response to recent carbon dioxide (CO2 ) shortage, MacCarb has been dedicated to servicing their customers and has provided emergency gas supplies from California to New York. “My goal is to grow my business without increasing resources,” says Dave McCarthy, Vice-President and Chief Financial Officer of MacCarb. “To do this, I need to reduce my number of visits by 50% per year. I can do this with Pulsa. And I’m saving my customers delivery fees and fuel surcharges.”

Moving to a connected gas world

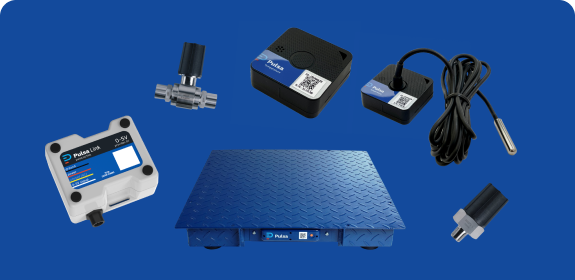

Historically, it never made sense to deploy telemetry at scale across most packaged cylinder gases. The costs, installation complexity, and reliability of telemetry solutions made very little sense for non bulk gas customers. The technical limitations have forced distributors to often over-service their customers in the form of check stops, or to run customers out if they can’t catch their inventory levels quickly enough. Fortunately, for gas users and distributors, modern remote monitoring systems have significantly decreased in complexity and cost. With simple setups, low costs, increased reliability, and purpose built sensor types, remote monitoring is now a highly viable opportunity for distributors to use across their fleet to decrease their own operational costs and improve levels of service with end customers.

A new level of customer service

In a highly competitive environment such as packaged gas, customer satisfaction is the key to ongoing success. High frequency telemetry, such as Pulsa’s system, provides precision inventory levels and fewer business interruptions for the customer. It also provides operational insights that can provide outsized return on investment (ROI), by identifying problems that can easily escalate into costly issues. For many, recognizing issues early on is key. “We detect problems before our customers do,” says Rob Caton, Beverage Sales and Support for Welders Supply & Gases of Louisville. “Whether it’s a leaky bag in a box or if they blew a keg, we can save the day now with Pulsa.” Being able to identify and solve problems before they escalate is a prime point of ROI for both distributor and customers, and the keystone benefit of high-frequency telemetry. Pulsa sensors send readings every three minutes, providing near real-time intelligence that’s revolutionizing customer service. “Customers call us when they need help,” says Kelly Netherton, Bulk Technician for Welders Supply & Gases of Louisville. “They’ll tell us they have no house line pressure in the building. With the headspace sensors installed, we can remotely read their pressure. We’ve been able to let them know that the vessel is at operating pressure, and that, more than likely, someone has closed a valve between the vessel and the point of use. Pulsa saved the day and saved a drive out to the facility.”

Business intelligence delivers a return

Pressure monitoring and weight scales are just two ways that telemetry is helping distributors deliver superior customer service. To provide even more insights and value to beverage gas and life science customers, Pulsa has just introduced two new sensors for temperature that provide additional benefits and ROI. Engineered for a wide range of refrigeration environments and beverage lines, the temperature sensors can identify anything from an immediate spike to slow changes over time – either of which can degrade or even ruin costly inventory. Monitoring solutions such as these provide the customer – not just the distributor – with the tools to reduce and even eliminate inefficiencies that cost both time and money. Showing customers the ROI for these new solutions becomes simpler as more and more distributors join the telemetry revolution and legacy challenges become yesterday’s news. “When we looked into returning to

“We’ve reduced top off stops, minimized the number of active delivery days”

micro bulk service and CO2 delivery, we knew we wanted to use telemetry on all accounts,” says Josh Edwards, Beverage Division Manager for Kint Beverage Concepts. “We settled on Pulsa and our choice has been confirmed. It has allowed us to expand into remote temperature monitoring as well as CO2 parts per million monitoring in our facilities.” By powering formerly manual procedures with near real-time intelligence, distributors can achieve a variety of efficiencies that all lead to increased profit. Fuel costs go down when there are fewer truck movements. Dispatching costs go down when they’re only scheduled when needed. Driver costs go down when unnecessary trips are eliminated, along with the back-office labor to schedule them. All this leads to optimal business operation for both distributor and customer.

And the upshot?

“We’ve reduced delivery check stops, we have significantly reduced weekend emergency fills, and have maximized CO2 fills,” says Bill Markle, Operations for Roberts Oxygen. “Because of telemetry, we are able to obtain a better accuracy in keeping up with peak flow demands within the business while securing a prompt delivery year-round.” It’s easy to see how savings like these, calculated across an entire customer base, can transform the entire distribution enterprise. In a business environment where competition is stiff and margins are tight, today’s successful distributors are embracing a new mindset – one that positions efficiency as an ROI for the customer, as well as for the distributor itself.