- 3 min read

- Media Coverage

- Wireless telemetry As featured in Gasworld: Dec 2021

- Blog

- Alerts

- Technology

- Equipment & Supplies

- Operations

- telemetry

- 3 min read

Wireless telemetry

As featured in Gasworld: Dec 2021

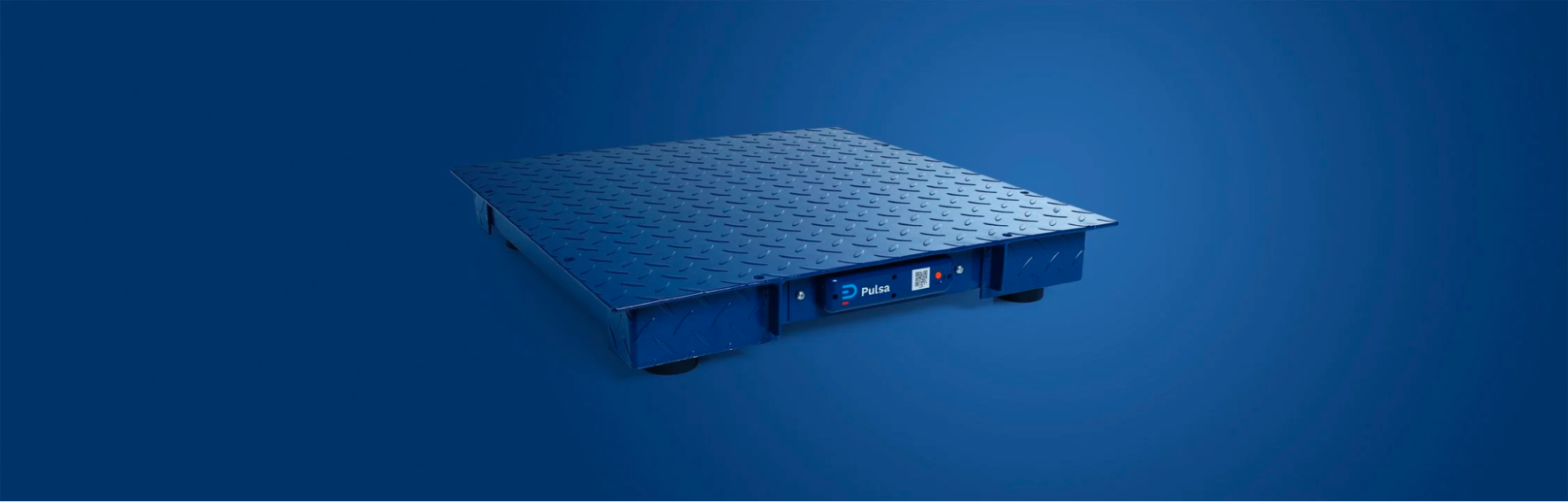

Wireless high frequency telemetry, which has been led by Pulsa’s offerings, has helped transform the traditional gas distribution supply chain. Historically, telemetry has been used by distributors for large bulk and microbulk operations, and the introduction of affordable wireless telemetry has changed the landscape to enable monitoring of all packaged gas assets. The Pulsa team has written about these changes at length in gasworld (https://www.gasworld.com/open-access/telemetry-not-just-for-bulk-gas-anymore/ and https://www.gasworld.com/high-frequency-telemetry/2021216.article) and that transformation across the industry is exciting, with millions of assets in scope for close to real time monitoring with sensors. The food and beverage industry in particular has reaped the benefits of wireless telemetry, and there are a few key drivers for why adoption has been so rapid in the food and beverage space. The current drivers for telemetry adoption include homogenous gas assets across food and beverage, low costs and margins for gases common in food and beverage applications, complex environments in restaurants and bars, and the need to wirelessly monitor many different environmental assets.

Single homogenous gas assets in food and beverage applications

Gas distributors often deliver more than just one gas asset to their end customers. End customers for manufacturing, laboratory, and medical applications often require different gases and hard goods from their distributor, which means that gas distributors often have to visit their end customers regardless of gas inventory.

However, most beverage customers only purchase CO2 from their distributor, which means that a single sensor monitoring gases provides distributors with ample visibility to understand when they need to visit their end customer, leading to significant cost and time savings for both distributors and customers.

Low cost and margin beverage gases

The business case for telemetry on beverage gases seems counterintuitive at first glance. While bulk gases are typically higher margin and more expensive gases that require telemetry, gases for food and beverage applications (e.g., CO2 , nitrogen) tend to be lower cost and margin. However, this ultimately is one of the major drivers for why telemetry is so critical on beverage gases.

Since the margins for these assets are so low, distributors need to keep distribution costs low to turn a profit while servicing CO2 customers. And while existing costly wired telemetry solutions are expensive from both a service, hardware, and installation perspective, wireless high frequency solutions like Pulsa give distributors an affordable option to only visit end customers when necessary, thus saving costs for both end customers and distributors.

“We have been able to leverage Pulsa’s technology to optimize our supply chain for monitoring both beverage and bulk gases,” said Denver Ockerman, Vice- President of Operations at American Welding & Gas. “In particular for beverage gases, we had been looking for an easy to install and reliable telemetry solution to help us monitor bulk beverage gases, and Pulsa has helped us provide better service to our customers while keeping costs down for both our customers and AWG.”

Environmental complexity

Unlike labs, manufacturing facilities, and medical facilities which are typically controlled environments, food and beverage gas tanks are often installed at bars and restaurants with heavy foot traffic. This often leads to installation complexity and unexpected wear and tear, which frequently leads to damaged equipment that requires troubleshooting.

High frequency telemetry providing readings every few minutes allows end customers and distributors to quickly troubleshoot errors and catch issues with piping, bag in the boxes, and other local environmental concerns quickly and reliably.

“It comes down to running as efficiently as possible and filling locations when they actually need to be filled,” said Dave Garner, Regional Manager at Roberts Oxygen. “In beverage applications, product usage can change, and getting frequent remote readings allows us to catch small problems and fix them before they become larger problems. Telemetry like Pulsa’s helps us identify issues and fix those issues with the least impact to the customer.”

Complete environment monitoring

Monitoring CO2 (and sometimes nitrogen) alone provides significant benefits to the distributor and end customer in terms of improved service, operational efficiency, and costs. The business case has been proven and both customers and distributors benefit greatly from high frequency telemetry deployments.

There are also a bevy of different sensors which can be used with wireless high frequency telemetry solutions like Pulsa that can provide additional information about other critical environment assets, like temperature and ambient CO2 levels. The wireless nature of sensors like Pulsa’s enables a simple and quick installation that doesn’t require mounting or cabling, especially when monitoring multiple assets. Not only does the end customer no longer have to worry about their gas inventory, but they also get close to real time remote monitoring of other critical assets with simple wireless battery powered sensors.

Josh Pringle, Executive Vice President at CO2Meter, Inc. said, “Customers are asking us with increasing frequency about how to remotely monitor variables like their tank levels and the CO2 safety monitors data. CO2Meter is excited about the opportunity to leverage Pulsa’s wireless technology to provide shared customers remote visibility into their CO2 safety monitors data.” Distributors and end users of food and beverage gases are constantly looking for ways to improve reliability, support, and costs of their gas assets, and that’s why high frequency wireless telemetry like Pulsa is seeing significant growth.